Fiber Reinforced Polymers

Characteristics and Behaviors

The mechanical properties and behaviors of fiber reinforced polymers (FRP), including composites with aramid (AFRP), basalt (BFRP), carbon (CFRP),

and glass (GFRP) fibers, versus steel reinforcing should be understood prior to undertaking the design of structures using these reinforcements.

FRP systems are an increasingly acceptable alternative to steel reinforcement for reinforced concrete structures including cast-in-place and pre- and post-tensioned bridges, precast concrete pipes, columns, beams and other components.

FRP advantages over steel reinforcement including resilience to corrosion is listed on the previous page. Masonry structures also benefit with FRP reinforcement. Their use as

original reinforcement and for strengthening structures is being specified more and more by structural engineers in the public and private industries.

Glass Fiber Reinforced Polymer (GFRP)

FRPs using glass fibers are the predominant reinforcing fiber in all FRPs. E-glass is the most commonly used fiber. It has high electrical insulating properties, good heat resistance, and has the lowest cost. S-Glass fibers have higher heat resistance and about one-third higher tensile strength than E-glass. The specialty AR-glass fibers are resistant to the alkaline environment found in concrete but have much higher cost.

Basalt Fiber Reinforced Polymer (BFRP)

Basalt fibers have higher tensile strength than E-glass fibers but lower than S-glass, however, its cost is near the cost of E-glass. It has much better resistance than E- and S-glass to the alkalies in concrete.

Aramid Fiber Reinforced Polymer (AFRP)

Aramid fibers (also known as aromatic polyamide fibers) have high strength, a high elastic modulus, and 40% lower density than glass fibers. The cost of aramid fibers is higher than glass and basalt fibers making them less common in structural applications. In addition, aramid fibers will absorb moisture so careful storage and planning of a project using aramid fibers is critical until the fibers have been impregnated with a polymer matrix.

Carbon Fiber Reinforced Polymer (CFRP)

Carbon fibers have a very high tensile strength and elastic modulus. The elastic modulus of “high modulus” carbon fiber is similar to steel. CFRP using high and ultra high modulus carbon fibers are popular in the aerospace industry because its strength to weight ratio is among the highest of all FRPs. High strength, normal modulus fibers are used with CFRPs in the civil infrastructure industry.

FRP Design Properties

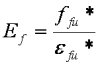

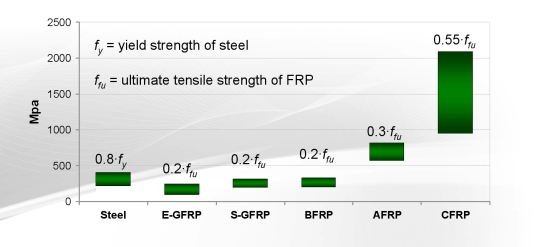

The primary physical properties considered for design are: (American Concrete Institute (ACI) nomenclature shown)

- Ultimate tensile strength, ffu*

- Tensile Modulus of Elasticity, Ef

- Ultimate Rupture Strain, or Elongation at Break, εfu*, the strain of a material at the point of rupture.

Fiber reinforced polymers exhibit linear-elastic behavior; therefore, these properties are interrelated as defined by Hooke’s law.

|

Reinforcing Material |

ksi (MPa) |

ksi (MPa) |

ksi (GPa) |

percent | Steel |

(276-517) |

|

(200) |

| Glass FRP |

|

(480-1,600) |

(35-51) |

| Basalt FRP |

|

(1,035-1,650) |

(45-59) |

| Aramid FRP |

|

(1,720-2,540) |

(41-125) |

| Carbon FRP |

|

(1,720-3,690) |

(120-580) |

|

Note:

- It is understood that steel has an ultimate tensile strength, however, it is not used in design.

- The values given for the various FRPs are based on a typical fiber volume fraction of 0.5 to 0.7.

- ACI 440.6-08 specifies that glass fiber and carbon fiber based reinforcing bars have a tensile elastic modulus of at least 5,700 ksi (39.3 GPa) and 18,000 ksi (124 GPA), respectively.

Comparison of FRP Tensile and Steel Yield Strengths

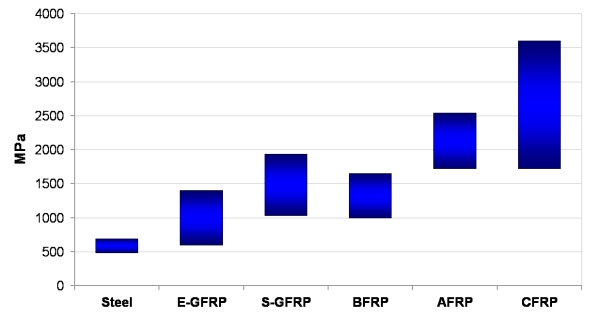

Creep-Rupture Stress Limit

An important factor when choosing the type of reinforced composite for a structural application is understanding the limits of a fiber to resist long term loading. Continuous and cyclic loading on a fiber reinforced polymer in excess of its ability to resist those loads may induce long-term deflection, fatigue failure, or creep-rupture in the structural component. To eliminate the deflections caused by creep, the stresses in FRP reinforcement in structural members must be less than the creep-rupture stress limit.

ACI and other design codes recommend a reduction factor applied to the ultimate tensile strength of the FRP to avoid creep-rupture and fatigue related failures. The reduction factors found in the ACI codes for glass, aramid and carbon FRPs are shown below. A reduction factor for basalt FRP is also shown based on acceptance by the Florida Department of Transportation (FDOT).

Creep-Rupture Reduction Factors

|

|

|

|

|

Creep-Rupture Stress Limit, Ff,s |

|

|

|

|

The creep-rupture reduction factors have a significant impact on the usable strength of the FRP system. The graph below shows the tensile strength range of the various FRPs multiplied by the appropriate creep-reduction factors along with the standard stress limit of 80 percent of steel yield strength.

Factored FRP Tensile Strengths

As can be easily seen above, carbon FRPs have a much greater usable strength after the application of the reduction factor. Greater usable strength equals a reduced amount of FRP for a given application which can offset increased material and labor costs.

Other design factors are needed to successfully design FRP reinforced structures. These will be discussed in later pages.

What is Your Fiber Reinforced Polymer Research Subject?

Got Research? Got Ideas?

Our world needs sustainable infrastructure and fiber reinforced polymer composites can meet those needs.

FRP Engineers, Students, Professors, and Scientists: Tell others about your research and your ideas here!

Share text, photos and graphics.

References Used on This Page

- Molded Fiber Glass Companies, “Designing with Fiber Reinforced Plastics / Composites, Techniques and Technologies for Cost Effectiveness,” 2003

- American Concrete Institute (ACI) Committee 440, 440.6-08 "Specification for Carbon and Glass Fiber-Reinforced Polymer Bar Materials for Concrete Reinforcement," 2008

- Prince-Lund Engineering, PLC, "Characteristics and Behaviors of Fiber Reinforced Polymers (FRPs) Used for Reinforcement and Strengthening of Structures," 2011

Return from Fiber Reinforced Polymers back to FRP Reinforcement Engineering

Return from Fiber Reinforced Polymers back to Prince-Lund Engineering, PLC Home Page

Prince-Lund Engineering

Quick Contacts

Email:

Go to the Contact Form to email directly.

Looking for Design Software? Try FRPpro™ free!

New! Comments

Please Ask Questions! Your Opinion Counts!